Allow me summarize the various materials you're likely to find used in wet areas of a disposer:

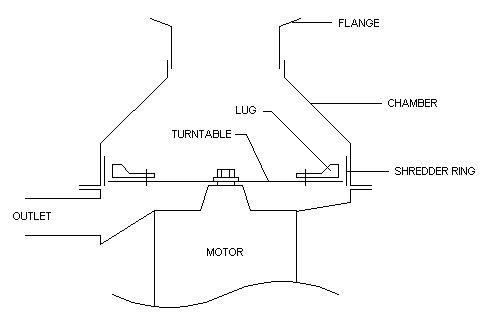

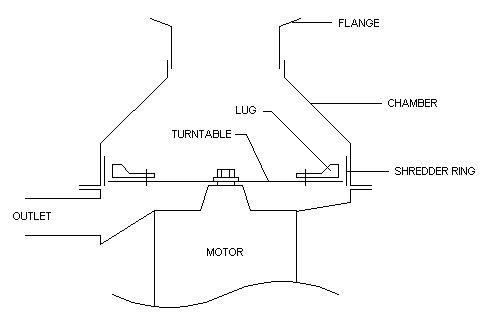

OK, let's talk about the components in the waste disposer itself. Here's a simplified drawing of the machinery involved:

Flange: The flange will almost always be made of stainless steel, because it's so plainly visible in the sink. In some really cheap models, the part may be made of plastic with a thin veneer of stainless steel up on top where it shows; you can easily see plastic down the sides within the hole, surrounding the area where the plug is inserted. Cheap, but it actually works OK.

In-Sink-Erator offers their sink flanges in white and almond enamel as well, for matching your decor. I suspect the enamel is over top of the stainless steel part.

Lugs: For some reason, the lugs almost always seem to be made of stainless steel, even in the cheapest models. It might be just so they can write the words "stainless steel" on the side of the box somewhere, hoping that nobody will notice that the more important parts are cheap junk.

Turntable: You really want this part to be made of stainless steel, but the cheaper models use galvanized steel here. Avoid such models.

Shredder ring: You want stainless steel here, too, even though this part isn't quite as visible from above as the turntable -- but once again, cheaper models will have galvanized here.

Chamber: On top-end models, this housing is made of stainless steel. On most other models, this housing is made of plastic. Either one seems to work fine. It's really difficult to see this thing from above without inserting a mirror in the hole.

Lower chamber: The lower half of the grind chamber -- the portion below the turntable -- and the upper end of the motor casing may, in fact, be one and the same part. This part is typically made of either molded plastic or cast pot metal. Plastic is better because it won't corrode, but one must admit this isn't too important; the cast pot metal part will probably last for decades, and nobody can see how yucky it looks without taking the outlet pipe off.

The bolt that holds the turntable to the motor shaft always seems to be stainless steel -- when there is a bolt. On really cheap units, the galvanized steel turntable may be welded onto the shaft.

The drain plug -- which I didn't show in the drawing above -- usually seems to be plastic, which works OK. In-Sink-Erator offers a plug made of plastic and stainless steel as an accessory. And, like their sink flanges, these plugs are also available with white or almond enamel on the metal.

Here's a couple of tricks to watch for:

When you look down the hole on the In-Sink-Erator model 444 (and the similar Kenmore 60563), the turntable appears to be stainless steel. However, if you look in through the outlet you'll see that the stainless steel disc is attached to a galvanized flange underneath. So it may look good from above, but you still may have a rust-related failure of this part down the road. Fortunately, it's not too difficult to get parts for In-Sink-Erator disposers, and it's not too difficult to replace that turntable. The top-end In-Sink-Erator models with model numbers that end in SS have the stainless steel disc attached to a stainless steel flange -- but the lower half of the grind chamber still appears to be pot metal.

There are several types of metal called "stainless steel", and some of them will not attract a magnet at all while others will attract a magnet weakly. Other than the center bolt, the stainless steel in the In-Sink-Erator models will attract a magnet strongly. In fact, you can't tell the stainless parts from galvanized parts with a magnet. This makes it pretty difficult to tell stainless steel from galvanized at all. Not much advice I can offer here, other than to suggest you look at some parts that you know are stainless steel and other parts that you know are galvanized until you are practiced at telling the difference. The stainless steel seems to always have a bit more tan in its color.

It won't be easy figuring out which parts are stainless steel by reading the box, either. Grainger, which sells In-Sink-Erator models, has a little chart in their catalog listing which parts are stainless -- but most retail stores are nowhere near as helpful. Some models claim they have "Stainless steel grinder elements" -- but what does that mean? Does that mean that all of the grinder elements are stainless steel, or does that mean that at least a couple of the grinder elements are stainless steel? And do they consider the turntable and the chamber to be grinder elements, or just the shredder ring and lugs?

Making the important parts of a disposer out of good

materials would only

add a couple of bucks to the cost. However, the boneheads in the

marketing

departments of these companies have apparently decided that if you want

good

materials, you also want mucho horsepower. Hence, finding a

well-built

disposer with less than 3/4 horsepower is a challenge, and of course

the

added power runs up the cost. My recommendation would be to pay

the

extra, even if you don't want or need the power; you really want the

good

materials.