MAYTAG / WHIRLPOOL WASHER BRAKE

In 1985, we purchased a Maytag washer and dryer set.

Recently, the transmission in the washer dumped its oil out the

bottom, making a royal mess all over the floor and all over the

belts and pulleys on the bottom of the washer. We actually

cleaned the oil off the belts and pulleys and kept using it for a

while; it kept right on working, although it was getting pretty

noisy.

After shopping for a new washer and dryer for a while, we decided

to fix the old washer instead! A replacement transmission is

readily available online (an orbital to replace the original

helical). In the course of rebuild, we discovered the washer

brake was also in need of replacement, but that is also readily

available online. All told, the parts were considerably

cheaper than a new Speed Queen -- the only decent washer we found

on today's market -- and we weren't interested in any of the other

cheap junk out there, including today's Maytags. Our old

dryer, which had been repaired a couple of times before -- new

motor, new heating element -- was still working fine.

The Maytag / Whirlpool brake assembly is a clever

contraption. After disassembling my old one and figuring out

how it works, I decided to post this page for others who might be

curious.

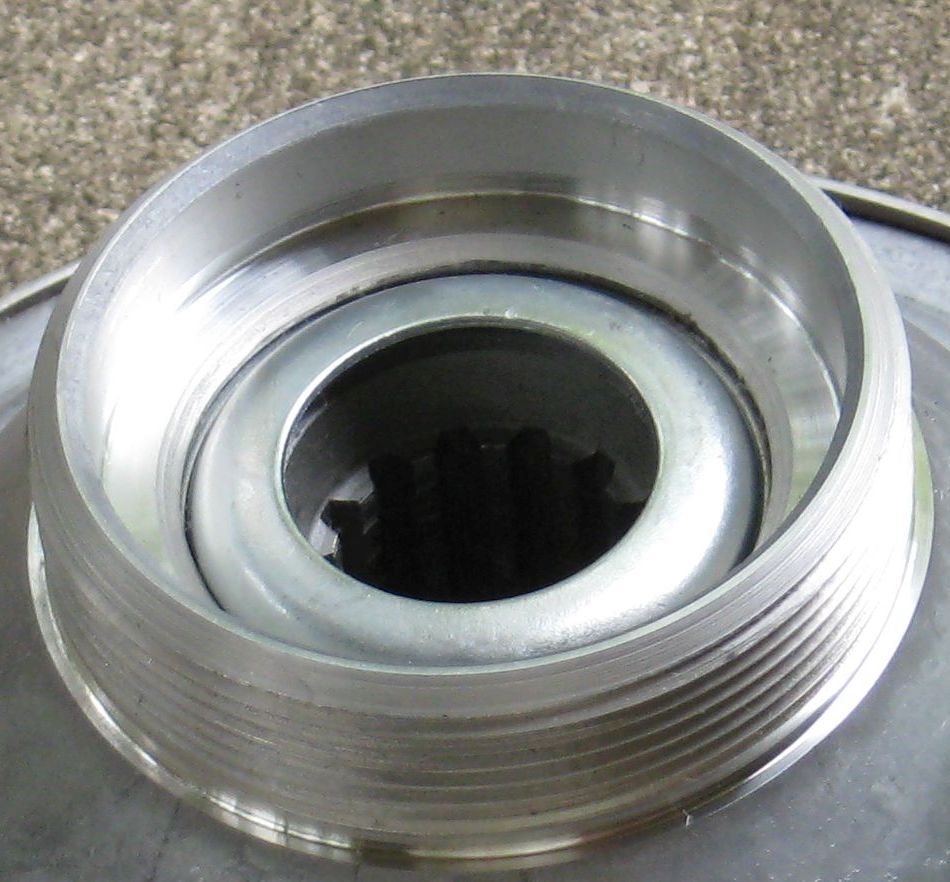

The new brake assembly is part number 6-2011900:

The old one was exactly the same except that it was held together

with screws instead of having the edges crimped.

The brake assembly also serves as the bearing holder for the lower

bearing supporting the transmission. The ball bearing, shown

in the photo above, is installed in the recess in the top of the

brake assembly prior to the brake assembly being screwed into the

tub support in the washer.

The brake assembly is spring-loaded, so a sticker is applied to

the old one warning to be careful when disassembling. With

the new crimped model, disassembly isn't as tempting, but there is

still a warning stamped into the sheet metal saying "Caution:

Spring Loaded - Do Not Disassemble". If you do choose to

disassemble one, as I did, you will want to take

precautions. If you have a really big vise, you can remove 3

screws, clamp the assembly into the vise and then remove the

remaining 5 screws. Carefully open the vise, and the brake

assembly will open up with it. If you have a bunch of screws

of the same thread only 2 inches longer, you can replace one screw

at a time with the longer screws, and then back out all the screws

progressively to gradually back the cover off. It wouldn't

be a bad idea to run a cord through the middle and around and tie

it into a loop to prevent parts from flying around if anything

goes wrong. But perhaps the easiest and safest method would

be to visit your local AutoZone and take advantage of their loaner

tool program to borrow a spring compressor. Insert the

spring compressor through the middle and tighten it down, remove

all the screws, then gradually release the spring

compressor. You might have to remove one or two screws

before applying the spring compressor.

If you're looking to disassemble the crimped type brake assembly,

I suppose the same ideas would apply except you have to carefully

unfold or grind away the crimps to get it open. To

reassemble, I suspect you can just rotate the cover a few degrees

to recrimp fresh metal.

Here's the exploded view of the brake assembly:

From left to right, I'll call these parts the brake housing,

spring seat, spring, brake disk, and brake cover with

screws. One screw didn't make it into the photo for some

reason. There was also a circular gasket for the bolt

flange, but it was oil-soaked on mine (it's supposed to be dry!)

and it came out in pieces, so I didn't include it in the

photo. Note that the brake disk has a brake lining bonded to

the outer edge, and it slides against a surface in the

cover. The spring applies the brake, meaning the brake is

normally engaged; when the motor turns the large pulley on the

bottom of the transmission, it winds up a corkscrew shaft and

presses the brake disk upward, disengaging it. There's a

ball bearing on the pulley itself allowing it to turn against the

center of the brake disk without friction or galling. As

long as the motor is running, it keeps the brake disengaged and

the wash tub spins. As soon as the motor shuts off, the

brake reengages to bring the wash tub to a prompt halt.

So far, simple enough. Let's get to what's clever about this

design. The brake disk rotates with the washer drum; it is

splined to the bottom end of the transmission. The housing

and cover are both stationary. That means that somewhere

between the disk, the spring, the spring cup, and the housing,

something's gotta slip. With the spring pushing these parts

together, they will not want to slip.

If you'll look more closely at the opening where the bearing is

installed, you'll see the center portion of the spring cup.

Note that the spring cup sits higher than the bottom shelf

of the bearing recess. As a result, when you slip the

bearing into this recess, it won't go down all the way; it runs

into that spring cup and sits with part of the bearing still

sticking out of the housing. As you thread the brake

assembly into the tub support on the washer, the bearing will

contact the surface in the recess in the tub support. As you

continue to tighten the brake assembly, the bearing will get

pressed down into the brake assembly, pushing that spring seat

along with it. This will lift the spring seat completely off

the inside of the brake housing. So, when fully installed,

the spring seat is only in contact with the inner race of the

transmission support bearing. Since that inner race rotates

with the drum, that means the brake disk, spring, spring seat, and

inner race of the bearing are all rotating together. Hence,

there should be no friction or wear between them.

I recommend carefully cleaning the threads on the brake assembly

and the tub support, and then applying anti-seize compound

(available at auto parts stores) to the threads prior to

installing this brake assembly. When installing, the brake

assembly should spin freely in the threads for several

turns. Then you should be able to feel the point where the

ball bearing makes contact with the tub support, and further

tightening is compressing the spring inside the brake

assembly. Then after some more turning, you should clearly

feel the threading come to a hard stop when the ball bearing hits

the bottom of the recess in the brake housing. It's a good

idea to get it pretty tight, but that's nowhere near as important

as making sure it's actually threaded on all the way! It is

imperative that the threads not be bound up or jammed prior to the

brake assembly being screwed all the way in.

By the way, I didn't buy the fancy tool number 038315. I was

able to get the old brake housing off using a hammer and a drift

on the four lugs on the back side. When reinstalling, I just

gave it a few taps to make sure it was snug. It's the little

locking tab, installed with a small bolt, that really ensures it

stays put.

Now let's talk about what was wrong with my brake assembly.

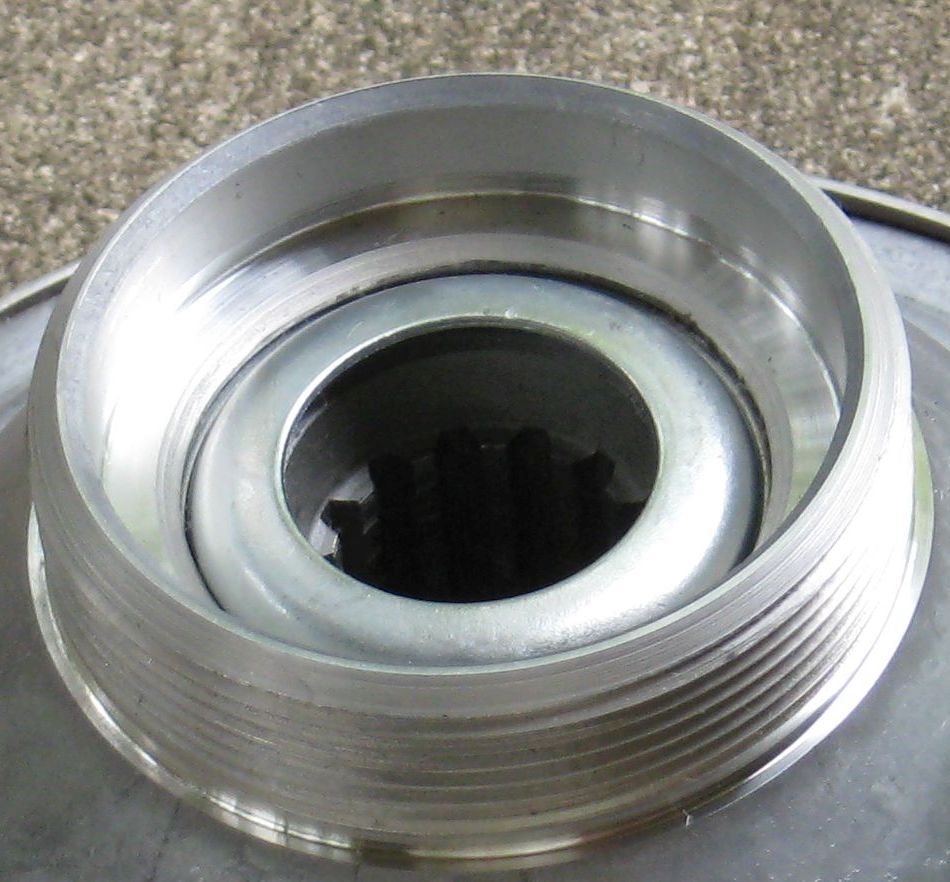

The spring cup looked like this:

It's worn very badly indeed, as you can see. It's as though

the spring seat has been grinding hard against the inner race of

the ball bearing. Thing is, these parts are supposed to be

rotating together, so there shouldn't be any wear at all.

What could cause relative motion and wear?

One possibility might be a seized bearing. If the bearing

locked up, the washer tub could keep right on turning by the shaft

of the transmission spinning inside the inner race of the bearing

-- it's not splined like the brake is, it's just a slip fit.

Thing is, though, my bearing seems just fine -- in fact, I

reinstalled it.

Another possibility is that something has jammed the spring seat,

preventing it from rotating with the brake disk. A chunk of

dirt getting in there might have fouled it; I didn't notice any

such chunks during disassembly, but since everything was covered

with oil I was preoccupied with minimizing the mess. It's

not obvious how any chunks would get in there, unless they were

accidentally dropped in during the original build.

Or, perhaps it wasn't installed correctly; if the brake hadn't

been screwed in properly, the spring seat wouldn't have been fully

lifted off the inside of the housing, and dragging against the

housing might cause it to start fretting against the bearing inner

race. This problem would compound itself, as the wear shown

in the picture would reduce the lift of the spring seat

and cause it to drag even more. In the photo above of the

seat itself, there's a worn spot at the upper left where the seat

has been rubbing against the inside of the housing, which would

seem to support this hypothesis -- but, on the other hand, that

could be a result of the damage rather than the cause.

The brake certainly seemed to be screwed on tight; I had to do a

reasonable amount of pounding to get it loose.

So, what actually caused this damage? I have no idea.

I only know that it's toast, a new brake is called for. If I

could buy the spring seat separately (79-cent part!) I could

rebuild the brake assembly good as new, but I didn't find

individual parts of this brake assembly online.

It might have been possible to rebuild and reuse this brake

assembly by milling or grinding that worn area of the spring seat

flat and parallel, reassembling the brake package, and then

reinstalling it with a spacer between the spring seat and the

bearing. The spacer would need to have the same ID and OD as

the inner race of the bearing, and it'd need to be roughly the

same thickness as the wear and milling had removed from the spring

seat since new. Suitable

spacers are available commercially, possibly locally at

hardware or bearing stores or Grainger,

or you could just fab one out of shim stock. You'll need to

have the transmission (or a dummy shaft) in place while screwing

the brake assembly into the tub support in order to hold the

spacer centered.

I do wonder if this brake damage was the cause of the noise the

machine was making. Yeah, the oil had drained out of the

transmission, but those gears are encased in an aluminum housing

and are probably still fairly well-lubricated by a film of oil on

the surfaces of the parts. I wouldn't expect the

transmission to be making much noise. With this spring seat

dragging, though, I'd expect it to make all sorts of racket, and

that racket would resonate through the spring and the brake

housing.