TECUMSEH GOVERNOR FAILURE

When this happened to my mower, I went online to see if others had

reported similar issues. All I found was guidance on how to

adjust a working governor, plus one small engines expert that

would offer advice for a fee. So, I'm posting my experience

in hopes of helping others.

SYMPTOMS:

I was just mowing along as usual, and all of a sudden the

engine started to "run away". It roared as though I had

given it full throttle, and revved way up. I cut the

throttle immediately, and was relieved the ignition

cutoff still worked. Upon further fiddling I found that the

engine would run at idle but the instant I moved the throttle just

a hair above idle the engine ran away and I'd have to cut the

throttle back again.

DIAGNOSIS:

I expected to find that a link had come loose or a spring had

broken or some such, but did not find anything out of sorts with

the linkage. The burning question: Did I miss

something, or is the problem really inside the engine?

Obviously, you want to make very sure the problem is inside the

engine before you go to the effort of opening it up.

Clarity arrived when I disconnected the linkage from the governor

lever and the lever flopped over in the CCW direction as shown in

this photo:

That's too far CCW; it shouldn't be able to move that far.

That confirmed that the governor inside the crankcase had failed

somehow and I'd need to open up the engine to fix it.

What's more, if I cranked the engine over slowly, the lever would

bump up a little bit a couple of times per turn. That told

me that the governor spool was AWOL and the lever was bouncing

over the flyweights on the governor gear.

TO DO NOW:

If you're even thinking about disassembling this

engine, here's something you need to do right now.

There are several bolts holding the oil pan or crankcase cover to

the crankcase; on my engine there are eight 1/4" bolts with 3/8"

hex heads. On my vertical shaft engine, the heads are facing

downward, the threaded ends point up. Some of them thread

upwards into bosses on the outside flange of the crankcase so you

can see the threaded holes on the top side of the flange. Right

now, go out there and spray some Liquid Wrench into those

holes so it can begin soaking down into the threads.

Get up from your 'puter desk and go do it!

Steel bolts threaded into aluminum castings are a recipe for

seized bolts, and breaking bolts during disassembly makes this job

a whole lot more difficult than it should be.

The Clymer manual on Tecumseh engines says to reinstall these

bolts with Loctite 242 (blue), and so did a slip of paper that

came with the replacement oil pan gasket. I won't be doing

that. Rather, I'll be reinstalling those bolts with

anti-seize compound -- just in case I ever have to get in there

again.

TEARDOWN:

The Clymer manual basically tells you how to tear down and

rebuild the entire engine, including the governor. You'll be

relieved to know you don't have to do all that other stuff if your

only problem is a broken governor. The procedure is as

follows:

- Drain the oil.

- Drain the gas, or pinch off the line and remove the tank.

- Remove the pulley or whatever is affixed to the shaft of

the engine. The key must be removed, too.

- You'll probably need to remove the engine from whatever

it's mounted on.

- Remove the crankcase cover (horizontal shaft engines) or

oil pan (vertical shaft engines). It was eight bolts on

my engine.

- Fix whatever's wrong with the governor and reassemble.

You will obviously need a new gasket for the crankcase

cover/oil pan. You also might want to consider replacing the

oil seal while it's so convenient to do so.

FINDINGS:

Upon removing the oil pan I found the spool broken as shown in

the photo at the top of this page. The spool had neatly

broken into three pieces; one remained on the governor shaft while

the other two were just sitting in the sludge inside the

crankcase. Since they hadn't been shattered or chopped into

a zillion pieces, it was easy enough to just pick the two pieces

out of the crankcase; no extensive cleanup needed.

Before the teardown, I pondered whether or not the failure might

be a wear issue; that the lever riding on the flat upper surface

of the spool had just completely worn through it. As you can

see in the photo below, wear on the surface of the spool was

negligible. This part broke just because it's a plastic part

that had too many years on it.

In general, plastic parts fail for one of three reasons:

- The plastic is exposed to sunlight; plastics don't like

UV radiation. Not a problem inside this crankcase.

- The plastic is exposed to excessive heat, causing it to

get brittle. That might be a factor here.

- The plastic is exposed to incompatible chemicals,

typically hydrocarbons or oil additives. That may be a

factor here as well, although I've always used the recommended

oil in this engine.

The current part number for a replacement spool is

30588A. They don't add the A for nothing; it indicates a

change of some sort, but not enough of a change to warrant an

entirely new part number. I'm hoping that the change is to a

different type of plastic.

In my experience with the Jaguar V12 engine, I've seen the arch in

its timing chain tensioner fail for little or no good

reason. I believe it's the same material as this spool, and

for the same reason: These parts have metal sliding across

them, and the plastic is a special formulation that is supposed to

minimize wear in such situations. Both the Tecumseh and the

Jaguar V12 are from the same era, so it was probably the state of

the art at the time.

THE GOVERNOR GEAR AND SHAFT:

I replaced the governor gear while I was in there even though

the old one was in good working order. Why? Because

it's plastic and it was 28 years old. It only costs about

ten bucks, and I'd just as soon not have to do this again.

The spool and the gear spin around a shaft that is pressed into

the oil pan. On mine, you pry off one clip and the spool

comes off, then you pry off another clip and the gear comes

off. According to the Clymer manual, though, some governor

shafts don't have the second clip. Rather, they have a

"boss" around the shaft that retains the gear. As a result,

the only way to get the gear off is to remove the shaft which is a

press fit into the oil pan. If this were the case in my

engine, I dunno if I'd replace that gear or not. Pulling the

shaft and pressing it back in to a specified depth is not a

trivial matter for a home mechanic, and entails more risk of

damaging the oil pan in the process. If I decided to go for

it, I'd have a spare shaft on hand.

REPAIRS:

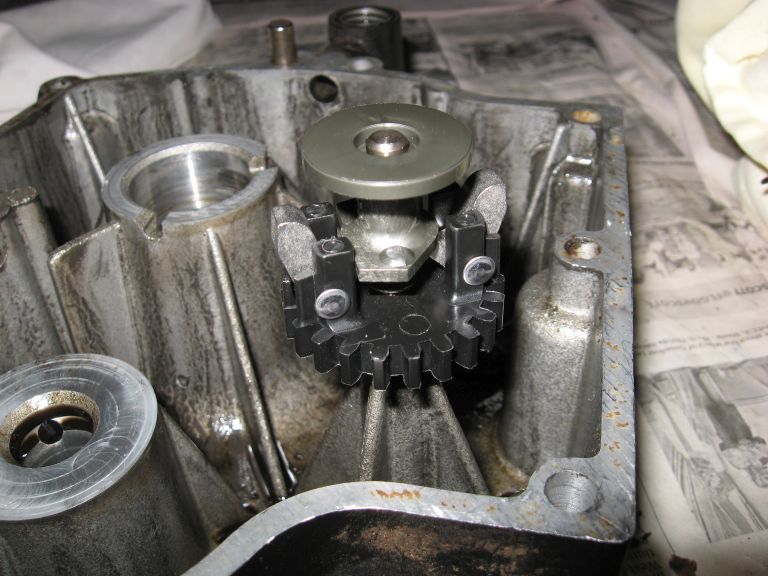

The replacement governor gear was black. Here's the

governor reassembled with new gear and new spool:

Actually, there are at least three differences between the old

gear and the new:

- Black vs. white (I suspect the old one only looked yellow

due to age)

- The flyweights are castings rather than stamped plates.

- The gear teeth directly outboard of the flyweights have

little posts sticking up that prevent the flyweights from

swinging farther out; they can't lay out flat like the ones on

the old gear in the picture at the top of this page.

These little posts should only make a difference during

assembly, I think; they hold the flyweights in the correct

position for installation of the spool. Once assembled,

the spool limits the motion of the flyweights.

Just for grins, I also took a picture with the governor in the

high-speed position, flyweights out and spool raised:

The governor lever rides against the flat surface on top of the

spool; as the spool rises, the lever moves to close the butterfly

on the carburetor.

After the engine was reassembled, the governor lever would no

longer move as far CCW:

That's as far CCW as it'll go. Compare this with how far it

would move CCW with a broken spool in the picture at the top of

this page, and you'll see why it became obvious that the governor

had failed and the engine had to be opened up.

As an aside: Upon reconnecting the linkage to this lever, I

realized that the linkage was not adjusted correctly. In the

Clymer manual it clearly stipulates that the linkage should be

adjusted so that when the governor lever is fully CCW -- the lever

inside the engine is in contact with the stationary governor --

the butterfly should be at wide open position. In this case,

when the butterfly was wide open the lever was perhaps 3/8" from

its fully CCW position -- and that's probably half its total

travel, meaning the lower half of the governor's control range was

inoperative. The governor had to move from its stationary

position to about halfway raised toward its fully extended

position before it'd even make contact with the governor

lever. I'm quite sure this linkage has never been fooled

with; I believe it was out of adjustment when it was originally

purchased. One could hypothesize that there was some

difference in the dimensions between the new vs. old governor

parts, but I don't think so.

It's easy to adjust: Just loosen the screw on the governor

lever (visible in the photo above behind the bottom end of the

spring) and then hold the butterfly wide open and the lower

portion of that lever (from the screw downward) CCW as you

retighten the screw. After adjusting the linkage properly,

the governor operation seems considerably better than it has ever

been. Specifically, it seems that I can adjust the running

speed higher than I could before without starting to close the

choke.

The following are presented as reference material related

to the governor repair described above:

GOVERNOR OPERATION:

Understanding how this governor works is helpful, but most of

the descriptions -- either in the Clymer manual or online -- are

clear as mud. So I'm going to provide my own description

here in hopes it'll make it more understandable for some.

I will be talking about four components:

- Governor (inside crankcase)

- Governor lever (part inside, part outside crankcase)

- Butterfly (in the carburetor)

- Throttle lever

The Tecumseh governor consists of a plastic gear with

flyweights (part number 30591) and a spool (part number

30588A). The gear is driven by the camshaft gear. As

the gear spins faster, the flyweights swing outward and push the

spool upward. Obviously on a horizontal-shaft engine the

spool is pushed sideways, but just cut me some slack here and play

along.

The governor lever consists of a metal rod that passes through the

crankcase wall with a stamped metal lever attached to it on the

outside. The portion of the rod inside the crankcase is bent

and shaped to ride on the surface of the governor spool.

The butterfly is the item on the carburetor that actually controls

how much air and fuel is allowed into the engine, and hence how

much power the engine develops.

The throttle lever is the device the control cable connects

to. It's the thing the operator moves to control engine

speed. On my engine it also engages the choke when moved

past the full-throttle point, but on other engines the choke may

be separate. There's also an electrical contact that shuts

off the ignition when the throttle lever is moved to the OFF

position.

The first thing to know: The governor lever and the

butterfly are firmly connected to one another by a link.

There are no springs or any other ifs, buts, or maybes in this

connection. One cannot move without the other

moving, period.

Governed speed control is a matter of balance between two opposing

forces. The throttle lever pulls on a spring that is trying

to speed the engine up; the farther the throttle lever is moved by

the operator, the harder the spring is trying to pull the governor

lever (and hence the butterfly) to the wide-open position to speed

the engine up. Meanwhile, the governor is trying to slow the

engine down. The faster the governor is rotating, the harder

it's trying to push the governor lever (and hence the butterfly)

toward the idle position to slow the engine down.

Hence, when the governor breaks -- the spool fractures and drops

into the crankcase -- the spring connected to the throttle lever

is free to speed the engine up unabated. Runaway engine.

There is a spring on the butterfly itself that's moving it towards

idle, but this spring is very weak and is not a significant player

during speed-governed operation. However, when the operator

moves the throttle lever all the way to idle, the spring that

pulls on the governor to speed the engine up goes totally

slack. The engine is turning slowly enough that the governor

isn't doing anything, but the light spring on the butterfly will

actually move the butterfly to idle and lift the governor lever

completely off the spool on the governor. Hence, idle is not

governed, but rather is set using an idle stop screw on the

carburetor.

THIS PARTICULAR ENGINE:

My engine is a vertical-shaft 8HP cast iron sleeve model TVM195

purchased new in 1987. It was installed on an

already-clapped-out Sarlo 21" walk-behind lawn mower chassis that

a local mower shop sold to me for scrap value. The

self-propelling mechanism was discarded; this is a mower you've

gotta push. No safety interlocks, no grass catcher.

8HP on a 21" mower may sound like overkill, but the purpose here

wasn't just to cut grass. My property is 73 acres of woods,

and I assembled this mower for the express purpose of cutting

walking trails through those woods. It's expected to cut

pretty much anything and everything I can roll it over, including

shrubbery, tree roots, small woodland creatures, you name

it. I have used it to cut paths through chest-high

weeds. The 8HP Tecumseh was chosen expressly because it's

the largest engine I could find that would fit between the tall

wheels on the Sarlo. The exhaust blows out through the

spokes on the right side wheel because there's no room to route

the exhaust any other way.

It actually has rather low hours on it; I probably don't run

it more than 20 hours a year, and even less lately because my

woods have thinned out and the trails don't require as much

upkeep. When it's run, though, it's run pretty hard, and the

governor probably gets a pretty good workout between patches of

nothing and patches of heavy ground cover.

Overall, it's been a good engine. I've had to replace the

starter cord and handle a couple of times. Before this

governor issue, the only serious problem I've had was a carburetor

float that started leaking and sank. When I replaced the

float I also rebuilt the carb, and it turned out one of the parts

in the carb rebuild kit was defective, so that task turned into a

fiasco until I finally figured out what the problem was.

Once sorted, though, it resumed starting easily and running

strong.

I'm probably not as scrupulous about changing the oil as I should

be. I never change it more than once a year due to the low

hours -- no need to change the oil when I'm not using the mower --

and sometimes it probably goes a couple of years between oil

changes. The oil always comes out still looking oily,

though; I've never waited so long that it came out looking watery

or gooey.

REPLACEMENT PARTS:

I mention the part numbers of the governor gear (30591) and

spool (30588A) in this page. These are the parts that fit my

TVM195. However, it's my impression that these same governor

parts fit all Tecumseh engines. Smaller engines

presumably have smaller camshaft gears, which means the engine

would have to turn faster to turn the governor at the same

speed. Hence, the same governor would efficiently control a

smaller engine at a higher RPM, which is usually what you're

looking for anyway. Pretty smart design on Tecumseh's part,

I think.

Replacing the governor requires a new oil pan gasket. In the

case of the TVM195, this gasket is part number 37342 -- which

superceded 35262 or 35262A, which superceded 33253, otherwise

known as G310 or 470-443. Clear? Actually, I suspect

there are minor differences there; for example, the 37342 I

received has odd little red rubber beads printed on one side,

while I suspect the earlier gaskets were plain paper.

Whatever, my decision was to apply Hylomar to both sides, as

Hylomar should make it easier to come back apart later. I'm

not a big fan of having to carefully scrape old gaskets off

machined aluminum mating faces, and it shouldn't ever be necessary

if the correct gasket dressings are used during assembly.